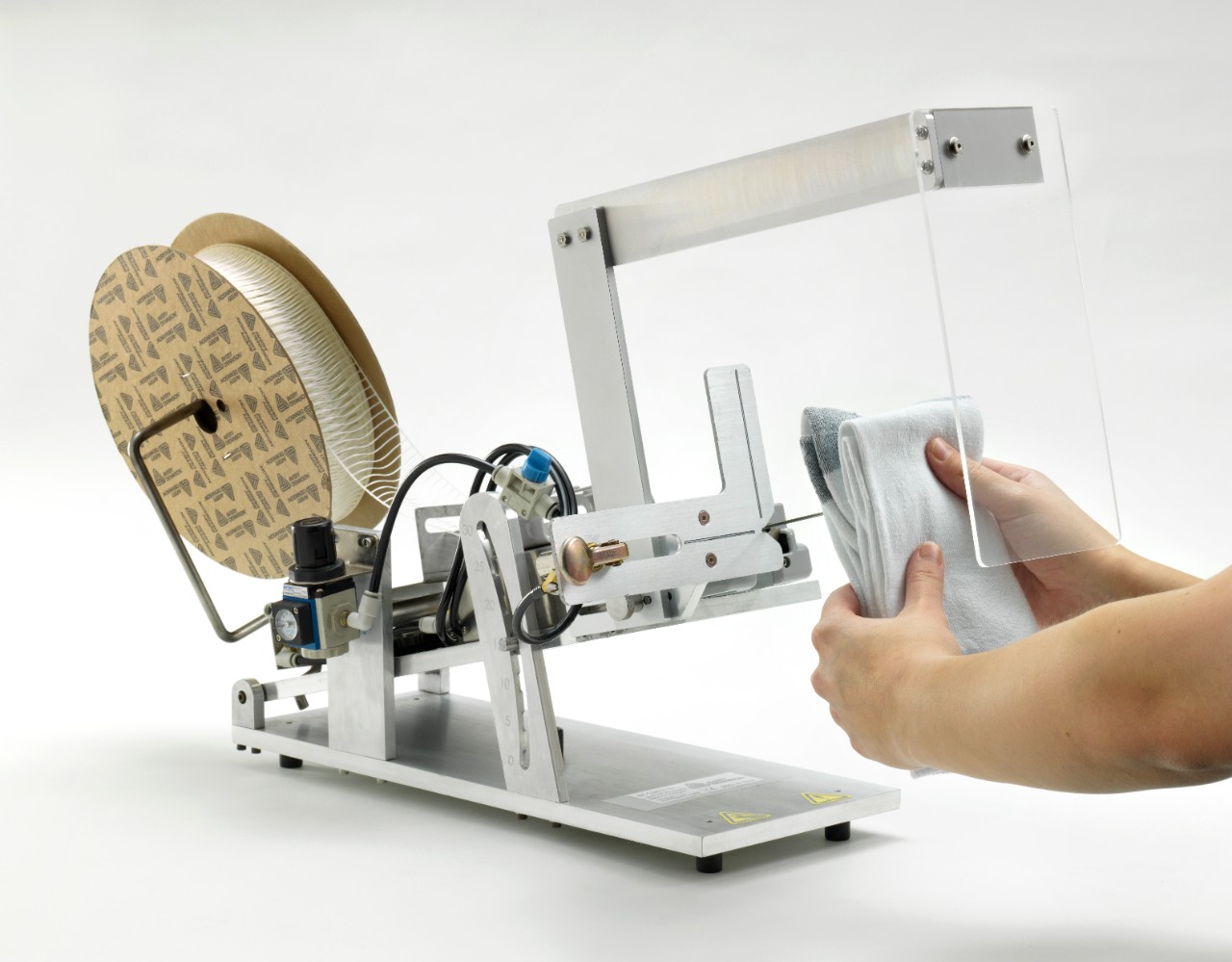

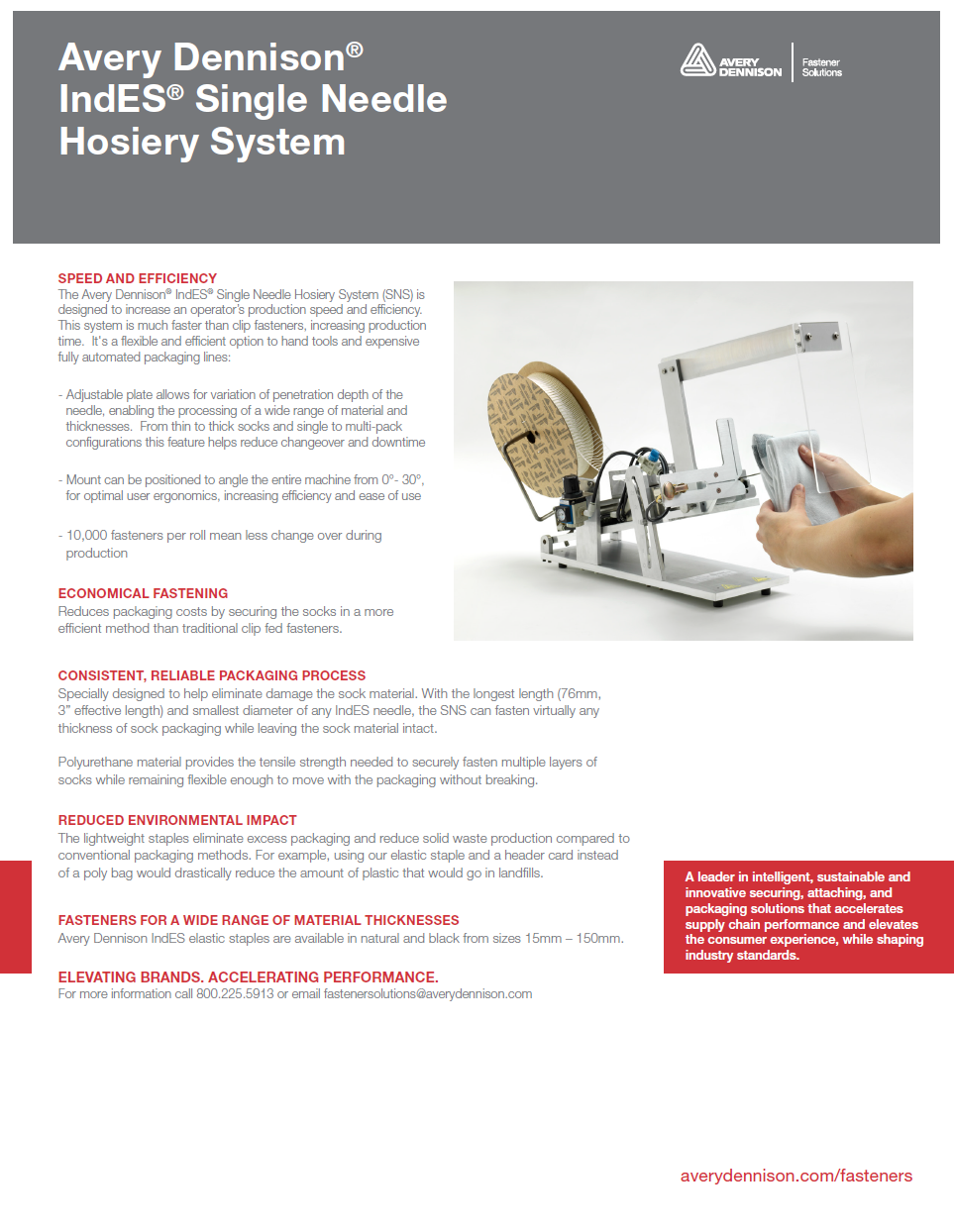

The Avery Dennison Elastic Staple® Single Needle Hosiery System (SNS) is a new and innovative packaging solution. It’s designed to help elevate brands by using secure, yet flexible, packaging materials.

A definite “step up” from clip fasteners applied by hand tools, the SNS is much faster and can help to improve production time. It’s also designed to help decrease the potential of operators developing carpal tunnel syndrome.

Features/Benefits:

Its adjustable plate allows for variation of penetration depth of the needle, enabling a wide range of material and thicknesses.

Its mount can be positioned to angle the entire machine from 0 degrees through 30 degrees for optimal user ergonomics.

It can accommodate 10,000 fasteners per roll, for less changeover time.

It secures products more efficiently than traditional clip-fed fasteners, reducing cost.

It can fasten virtually any thickness of sock packaging while leaving the sock material intact. Polyurethane material provides the tensile strength needed to securely fasten multiple layers of socks while remaining flexible enough to move with the packaging without breaking.

Its lightweight staples eliminate excess packaging and reduce solid waste production compared to conventional packaging methods.

IndES elastic staples are available in natural and black, in sizes ranging from 15 millimeters through 200 millimeters.