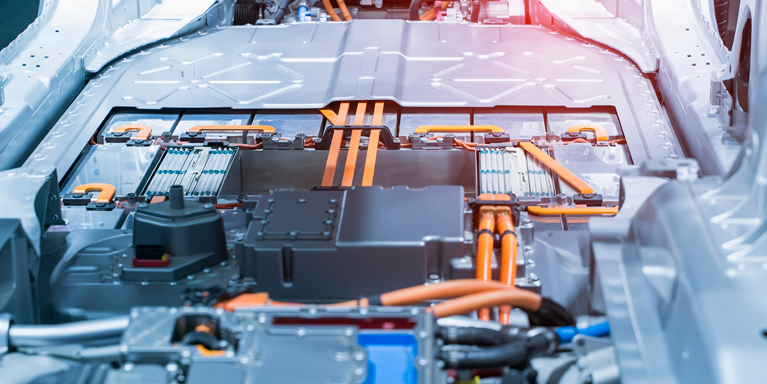

The shift toward electric vehicles (EVs) in the automotive industry has led to changes in the design and construction of vehicles, including the use of new materials, new technologies, and new standards. One area that has seen significant changes is the use of engineered fasteners, which are used to hold together the various parts of a vehicle. As EVs have different requirements than internal combustion engine vehicles, OEMs are now requesting different types of fasteners with unique features such as larger holes, higher extraction forces, and an oval shape. Bernardo Heiremans, Auto & Cable Ties Product Manager in Avery Dennison’s Fasteners Division, discussed with SAE’s Automotive Engineering how the company has responded to these changes by developing a complete portfolio of oval clips to meet these new demands.

With the transition to EVs, is there a change in the type of engineered fasteners being requested by OEMs?

Yes, for EV applications, OEMs are demanding more-advanced and specialized fasteners to accommodate the larger and heavier wiring harnesses used in these vehicles. In the past, the 6.6-mm round hole was the standard size for internal-combustion engine vehicles, with panel thicknesses ranging from 0.7 mm to 7 mm. However, now many OEMs are moving from round holes to oval holes for better retention and to prevent rotation of the fastener. Additionally, in 2021 USCAR released a new 9x17-mm heavy-duty hole size, which is becoming popular for new EV platforms. This new size requires higher extraction forces to ensure the safety and proper retention of the harness within the vehicle.

What is the chief reason for larger holes on EVs?

The reason for larger holes on EVs is due to the thicker cables and larger bundle diameters that are used in these vehicles. This results in heavier harnesses that require more-secure fastening methods. Using a traditional fir tree fastener with a 6.6-mm hole and a minimum extraction force of 25 lbs. — as specified by USCAR 44 — may not be sufficient to hold the harness securely in place. However, by using a larger 9x17-mm hole and an Avery Dennison fir tree fastener, the harness is held securely with a minimum extraction force of 50 lbs. This ensures the safety and integrity of the harness in the EV.

You previously mentioned panel thicknesses, are there any changes there?

OEMs are constantly seeking ways to make vehicles lighter and more efficient, one of which is replacing steel chassis with aluminum. Although aluminum is lighter than steel, it also is weaker. To address this, manufacturers have been increasing the thickness of aluminum panels. Previously, the maximum panel thickness was 7 mm, but now there are requests for panels as thick as 10 mm or even 12 mm. To support these thicker panels, new fastening solutions have been developed, such as the 9x17 clip, which can be used in panels up to 12 mm thick and paired with a heavy-duty strap for added support and strength for the harness.

What steps has Avery Dennison taken to adapt to recent changes in the automotive industry?

Avery Dennison has developed a comprehensive portfolio of oval clips to meet the changing needs of the industry. This includes clips for 6.5x12.5-mm holes in standard, 12.5-mm, and 25-mm standard and reverse offsets, a 2-piece option for use with heavy-duty and standard straps, and a long, 2-piece option for panel thicknesses of up to 16 mm.

What other strategies are available to improve the construction of EV harnesses?

Efficiency is a crucial aspect for any company, and this applies to the use of fasteners as well. By reducing the number of types of fasteners used, it can lead to a more efficient supply chain for the procurement team — and cost savings due to the reduction of parts in the bill of materials. Avery Dennison’s parts are designed to fit multiple hole sizes and our experts can provide customers with alternative solutions to reduce the number of parts used, as well as other cost-saving ideas.